摘 要

汽车后桥差减速器的装配质量是影响整个汽车性能的一个重要因素。然而到目前为止,为了满足差减速器内主齿总成的装配质量要求,大部分厂家先通过经验选择垫片种类及片数,再由压装后检测预紧力矩来确定垫片选择的正确性,如果预紧力矩过大或过小,都应拆卸主齿总成反复试装;而为了满足差减速器内主、被动齿轮的啮合要求,大部分厂家选片方法多数采用涂粉、试垫,再由装配后检查啮合印痕是否正常,以确定选择的垫片是否能保证主、被动齿啮合良好,否则应反复试装进行调整。这些方法过程繁琐,效率低下,不适应汽车行业的发展。

汽车后桥的装配质量主要受两个因数影响,一个是主齿总成的装配质量,另一个是差减速器内主、被动齿轮是否啮合良好。后桥差速器壳体结构复杂,不便测量,传统的测量方法是手动测量及一些专用检具来进行测量,并且一套测量系统只能检测某种车型的的装配尺寸。而且测量方法有精度低、测量速度慢,干扰因素多等缺点。为了缩短测量时间,提高测量精度,提高测量的可靠性,本文提出了一种全自动高柔性的自动测量方法及其控制系统,并编制了实用的软件。

经过理论分析与实际程序的在线调试,证明此测量方法和控制系统能够实现自动测量装配主齿总成隔套垫片和主减速器壳体所需的装配尺寸,而且具有智能化、通用性强的特点。

关键词: 汽车;后桥差减速器;装配;自动检测

Abstract

The assembly quality of Automotive rear axle differential reducer is an important factor for the entire car performance。However, so far, In order to satisfy in the difference reduction gear the cusp unit assembly quality requirement, the majority of factories choose the type and the piece number of filling piece first through the experience, If pretightening up force moment oversized or too small, should disassemble the cusp unit counter-second examination attire; But to satisfy in the difference reduction gear main, driven gear's meshing request, the majority of factory chip select method uses Tu Fen, the trial pad most, again after assembly inspects the meshing mark to be whether normal, by determined that choice filling piece whether can guarantee main, passive tooth meshing is good, otherwise should the counter-second examination attire make the adjustment. These method process is tedious, the efficiency is low, does not adapt the automobile profession development.

The automobile rear axle of car's assembly quality mainly two factor influences, one is the cusp unit assembly quality, another is in the difference reduction gear main, the driven gear whether to mesh good. The rear axle of car differential device shell structure is complex, the inconvenient survey, the traditional measuring technique is the manual survey and some special-purpose examines has carries on the survey, and a set of measurement system can only examine some kind of vehicle type assembly size. Moreover the measuring technique has the precision to be low, the survey speed is slow, disturbance factor many and so on shortcomings. In order to reduce the measuring time, increases the measuring accuracy, enhanced the survey the reliability, this article proposed one completely automatic high flexible automatic sizing method and the control system, and have compiled the practical software.

After the theoretical analysis and the actual procedure's online debugging, proved that this measuring technique and the control system can realize the automatic sizing assembly cusp unit to separate the assembly size which a set of filling piece and the main gear box shell need, and has the intellectualization, the versatile strong characteristic.

Keywords: Automobile;Rear axle of car difference reduction gear;Assembly;Automatic detection

目 录 20000字

第一章 绪论 1

1.1课题研究的意义 1

1.2汽车工业的现状和面临的挑战 1

1.3装配的概念 2

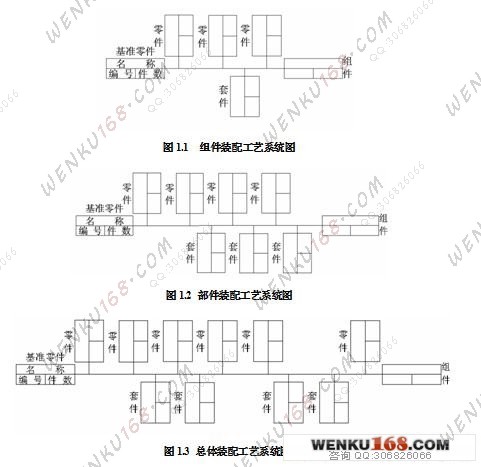

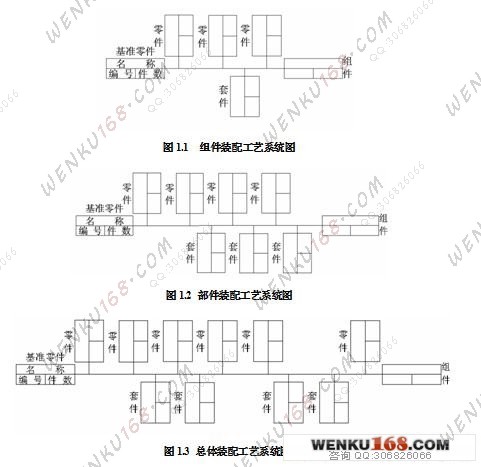

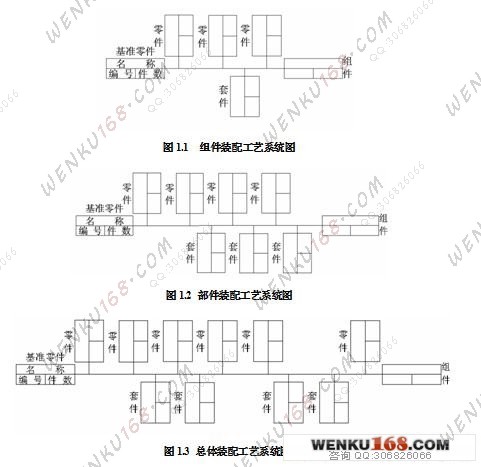

1.3.1装配系统图 3

1.3.2装配精度与装配尺寸链 3

1.4装配的组织形式 4

1.4.1不同生产规模下装配工作的特点 4

1.4.2确定装配的自动化程度时,一般应考虑一下因素 4

1.5装配方法 4

1.5.1互换装配法 5

1.5.2分组装配法 6

1.5.3修配装配法 6

1.5.4调整装配法 6

第二章 设计背景、原理与思路 8

2.1汽车工作原理 8

2.2汽车差速器 8

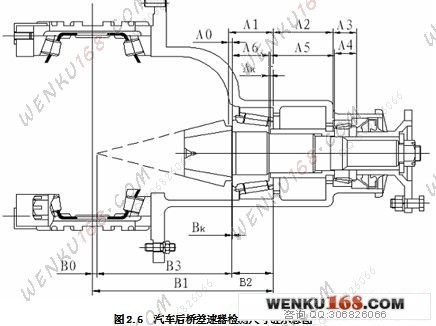

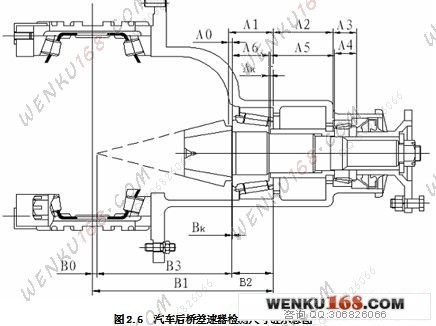

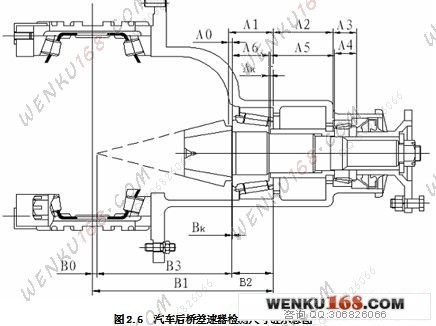

2.3汽车后桥差速器检测原理 9

2.4同类或相仿零件的检测原理与方法 9

2.5后桥差速器装配尺寸链 11

第三章、制定方案及总体设计 13

3.1装配尺寸自动检测仪方案选择 13

3.2总体设计 13

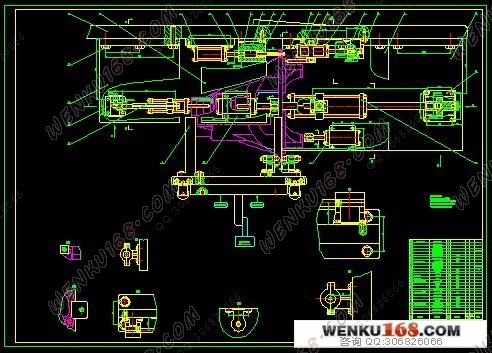

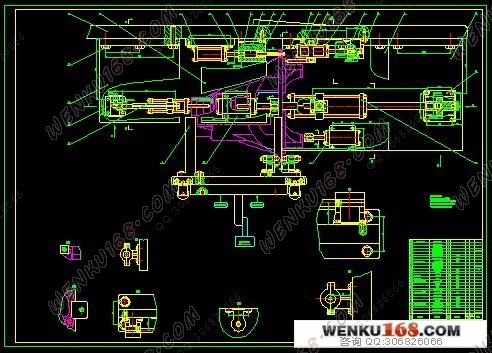

3.2.1检测部分 13

3.2.2随行夹具部分 15

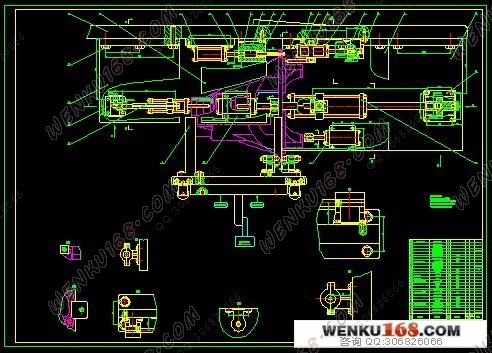

第四章 机械结构设计及零部件选择 17

4.1具体结构设计 17

4.1.1气缸移动结构设计 17

4.1.2检测气缸活塞杆固定件结构设计 20

4.1.3随行夹具检测时横向移动机构设计 20

4.1.4液压夹紧抬起机构液压缸的选择 21

4.1.5止口定位件及气缸支撑件设计 21

第五章 控制系统设计及控制元件选择 22

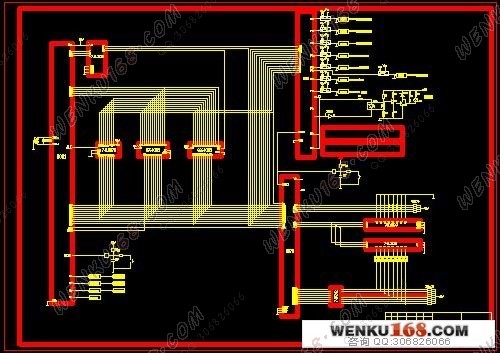

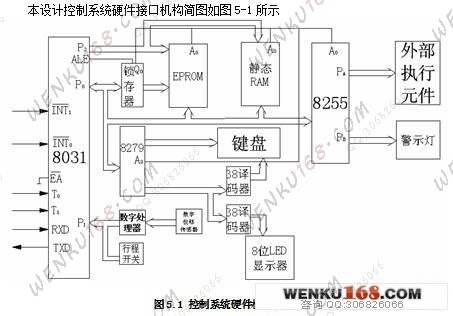

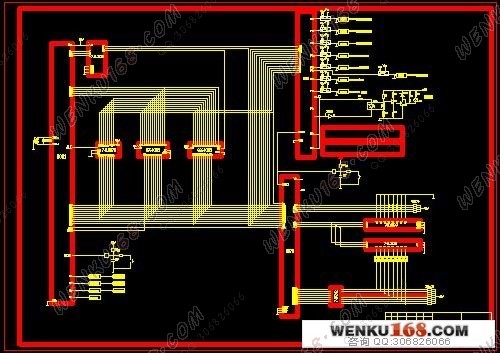

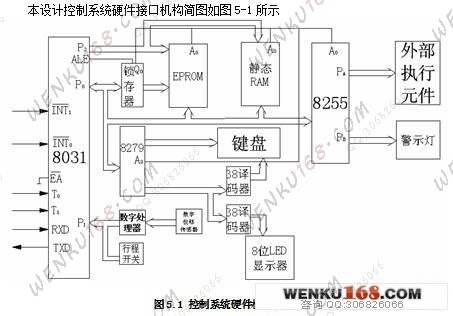

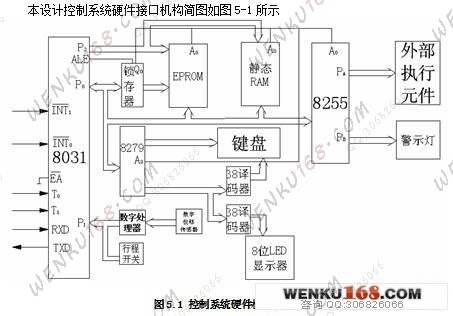

5.1控制系统总体设计 22

5.1.1 控制系统的总体结构 22

5.1.2 MCS-51单片机引脚及8031总线结构和引脚功能 22

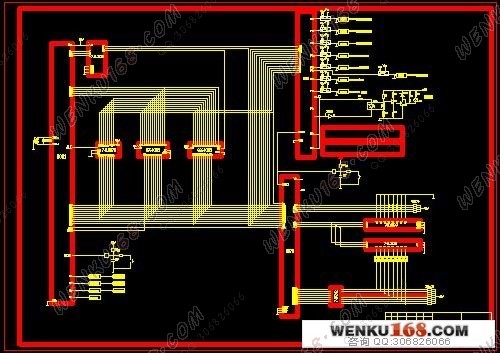

5.2单片机外部总线的扩展 26

5.2.1外部程序储存器的扩展 26

5.2.2外部数据储存器的扩展 28

5.2.3 8255可编程并行I/O接口扩展 31

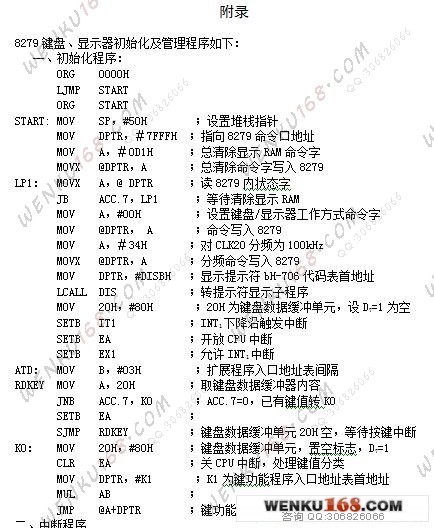

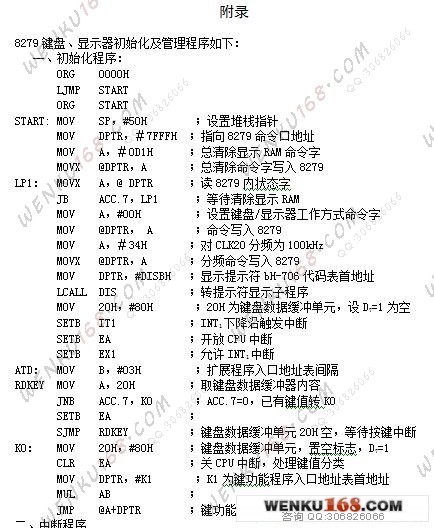

5.2.4人机联系接口技术 33

5.3传感器的选择 38

第六章 总结及未来展望 41

6.1总结 41

6.2课题的展望 41

致 谢 42

参 考 文 献 43

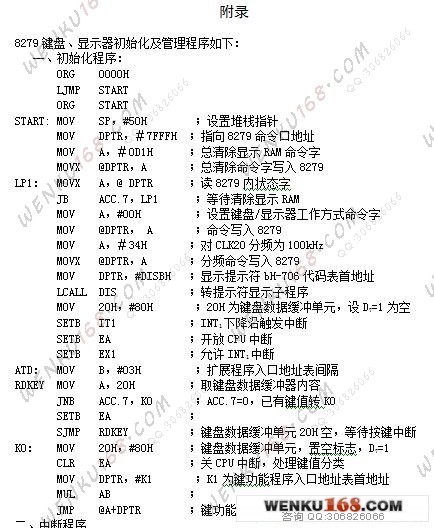

附录 44

|