弯板弯曲冲孔切断模的设计(附加工工艺卡)

来源:wenku168.com 资料编号:WK1683565 资料等级:★★★★★ %E8%B5%84%E6%96%99%E7%BC%96%E5%8F%B7%EF%BC%9AWK1683565

资料介绍

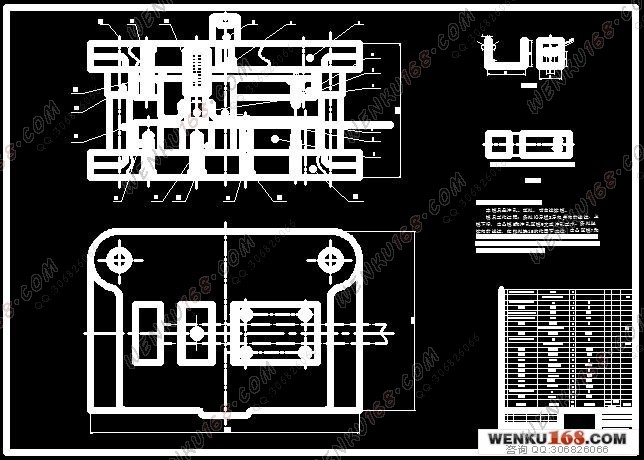

弯板弯曲冲孔切断模的设计(附加工工艺卡)(含任务书,毕业论文说明书9000字,cad图纸14张零件图1张装配图)

摘 要

本设计题目为弯板弯曲冲孔切断模设计,体现了冲压工艺的全部的设计要求、内容及方向,有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者冲压工艺的基础知识,为设计更复杂的冲压模具做好了铺垫和吸取了更深刻的经验。

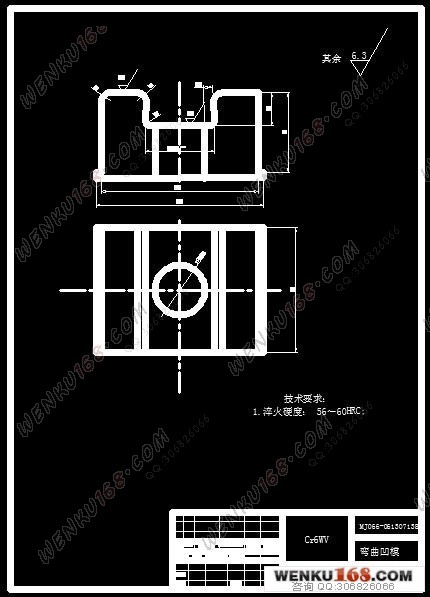

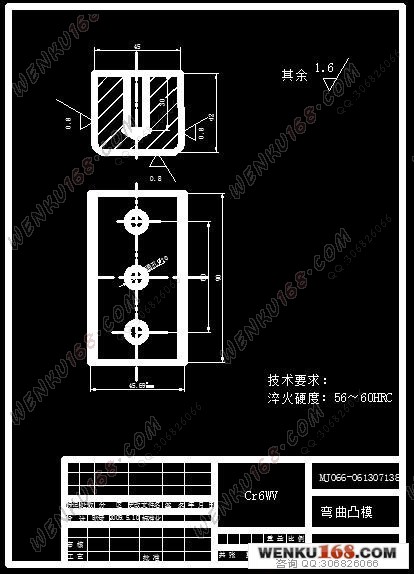

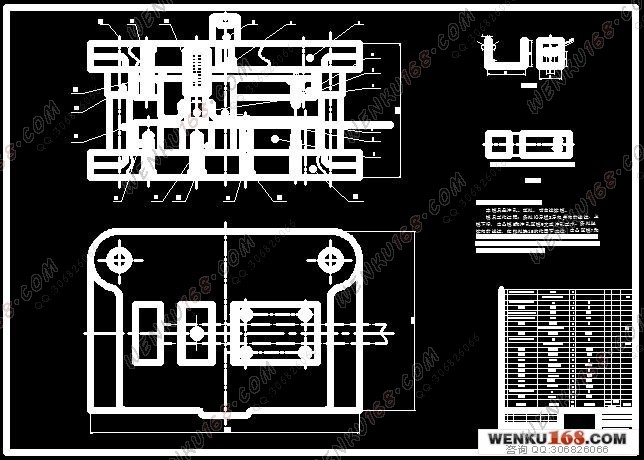

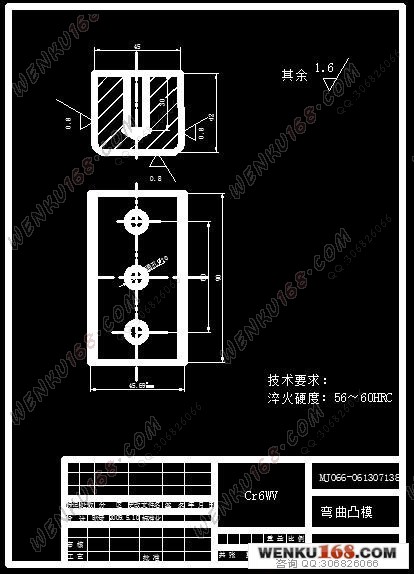

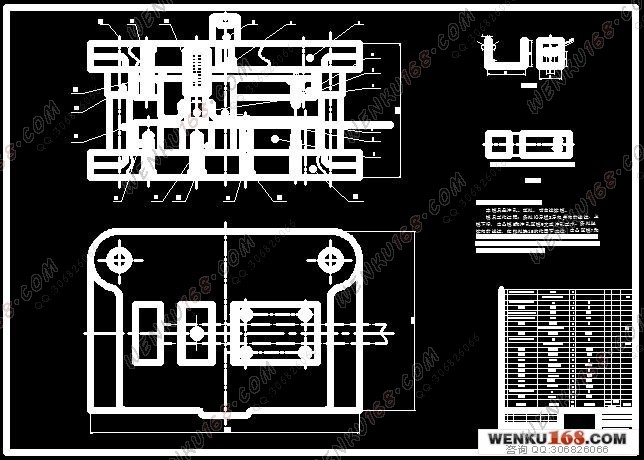

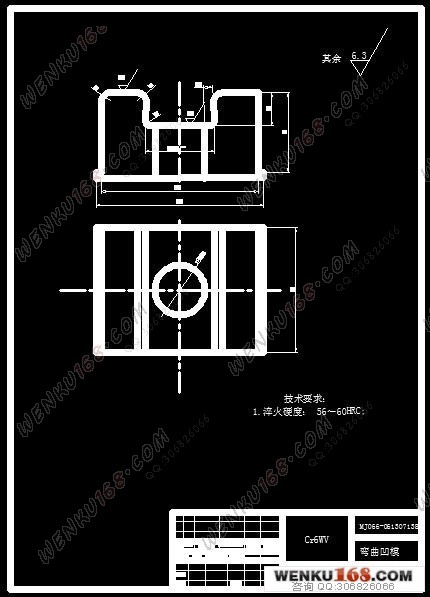

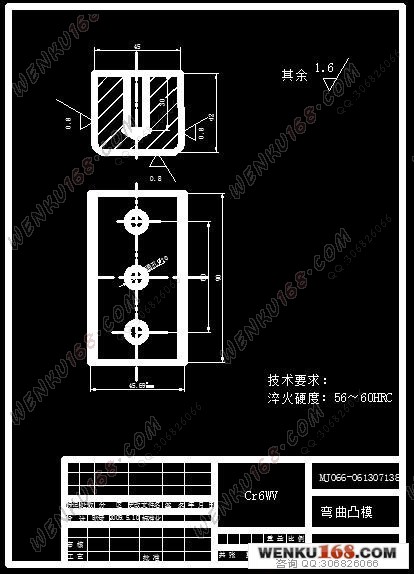

本设计运用冲压成型工艺及模具设计的基础知识,首先分析了制件的变形及性能要求,为选取模具类型做好了准备;然后计算冲压凸模和凹模的尺寸,便于选取标准的凸模和凹模做准备;最后分析制件的结构,以便确定凸、凹模的形状,分析制件材料力学性能及变形过程中的特点,以便计算冲压力的大小来选取压力机类型。

本设计是冲孔、切断、弯曲的级进模具,设计时主要考虑了不同工位之间的距离,以确定毛胚制件的位置及每次进给的距离。同时考虑各个不同工位之间动作的协调一致性及各个工位模具的磨损量。

关键词: 级进模 弯曲模 切断模 冲孔模

Curved plate bending punching and cutting mode

Abstract

The design for the curved plate bending subject punching die cut design, stamping process embodies all the design requirements, content and direction of the design of a certain significance. Through the design of the mold parts, has further strengthened the basis of the designers of stamping process knowledge, for the design of more complex stamping die to do a good job of paving the way and draw a more profound experience.

The design of the use of punch forming process and die design of the basic knowledge, the first analysis of the deformation of parts and performance requirements, in order to select the type of ready to die; and then calculating the punch press and die size, easy to select the standard punch and to prepare die; the final analysis of the structure of parts in order to determine the convex, concave die shape, analysis of the mechanical properties of materials and parts in the process of the characteristics of deformation for the purpose of calculating the size of red pressure to select the type of press.

The design is punching, cutting, bending progressive die, the main consideration for the design of the different distance between the position to determine the rough location of parts and the distance between each feed. Taking into account the different position of the coordinated action between the various work places and mold wear

Key words: composite die punching cutting bending

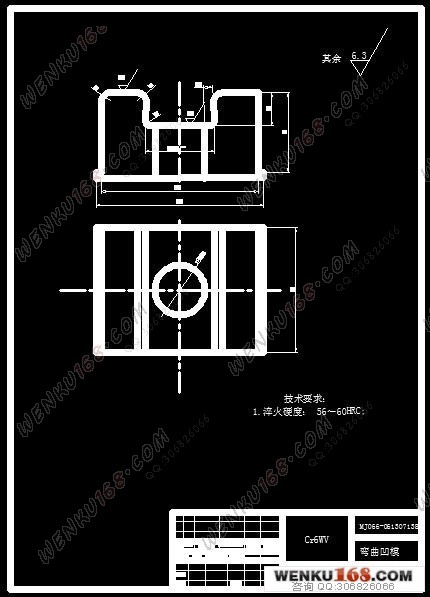

弯曲冲孔的工艺分析

为此工件典型的U形件,零件图中的尺寸公差为未注公差,在处理此类公差等级时常采用IT14级要求。弯曲圆角半径R为2mm,大于最小弯曲半径(rmin=0.6t=0.6×2mm=1.2mm),故此弯曲件的形状、尺寸、精度均满足弯曲工艺的要求,可用弯曲工序加工。

此弯曲件上有2个孔,需采用冲孔的方式加工,孔的直径为4.5mm,形状简单,且对称。冲裁件所能达到精度为IT11~IT14级。故该零件的精度要求能够在冲裁加工中得到满足。

|