后支架零件冲压模具设计(精品)☆

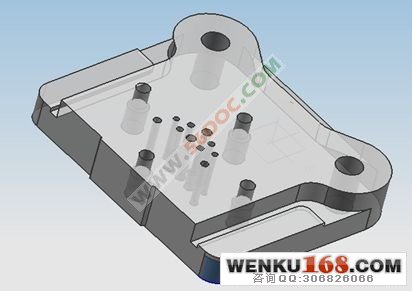

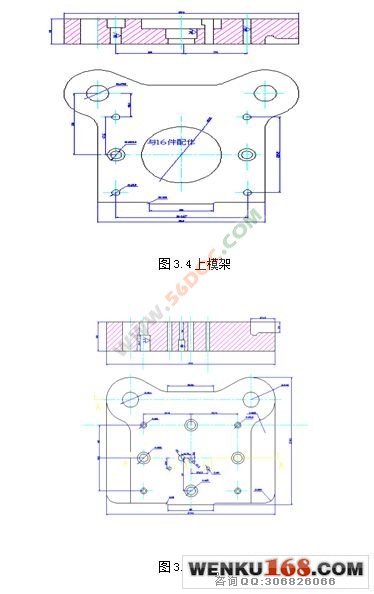

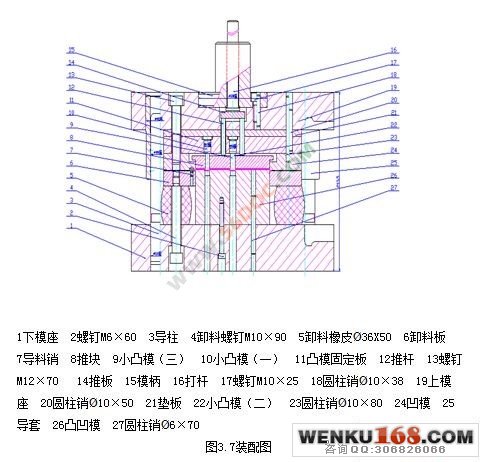

摘要:模具是现代工业生产中应用广泛的优质、高效、低耗、适应性很强的生产技术或称成型工具、成型工装产品,是技术含量高、附加值高、使用广泛的新技术产品,是价值很高的社会财富。 关键词:复合冲压,复合模,弯曲,模具设计 Abscract:Mold is a modern industrial production of a wide range of high-quality, high-efficiency, low consumption and strong adaptability of the production technology, or molding tools, Prototyping Tool products, high technological content and high added value, the wider use of new technology products, is the high value of social wealth. The main task of the issue is Textile Machinery Swing stamping process and die design. As the important components, textile needs high precision. The program is the first of blanking-punching composite punch, then bending modulus composite production. The design process: First, the program for the verification process and the various parameters, Die identify the major components of the structure and size, Cutting Edge for the calculation of the size and intensity of the relevant pieces of the check; Access to the relevant books, To Die standard components; Then calculated the entries drawn die assembly and non-standard components map, Further written statement.      目 录 12000字 1 绪论 1 1.1 背景 1 1.2 冷冲模成型的特点 2 1.2.1 冲裁模 3 1.2.2 弯曲模 4 1.2.3 拉深模 5 1.2.4 多工位级进模 6 1.3 冷冲模具的发展趋势 6 1.4 本文主要研究内容 8 2 工艺方案的选择 9 2.1 零件的工艺性分析 9 2.2 模具的结构形式 10 2.2.1 冲裁力和弯曲力的计算 11 2.2.2 卸料力、推件力和顶件力的计算 12 2.3 制定冲压的工艺卡 13 3 冲压模具设计 14 3.1 排样 14 3.2 模具压力中心的确定 15 3.3 压力机的选择 16 3.4 模具主要零部件的设计 16 3.4.1 冲孔凸模的结构设计 17 3.4.2 凸凹模的结构设计 20 3.5 冲压模具标准件的选择 21 3.5.1 模架的选择 21 3.5.2 挡料销 23 3.5.3 卸料装置 23 3.5.4 推件装置 24 3.5.5 导向零件设计与标准 25 3.5.6 模柄的选用 25 3.5.7 凸模固定板与垫板 26 3.5.8 冲压模具的结构图 28 结论 29 参考文献 30 致谢 31 附录 A 32 |