饺子机及输送成型部件设计(含任务书,开题报告,外文翻译,毕业论文说明书18000字,进度检查表,CAD图纸7张)

摘 要

dumpling是中国的饺子,是一个在中国很受欢迎的食物。通常来说饺子是一种团圆、幸福 、祥和的标志。

速冻食品作为一个日常消费品,在国内有很大的发展空间。目前,世界速冻食品总产量已超过6000万t,品种达3500种以上;其贸易量近期以年均10% ~30% 的速度递增。在我国,速冻水饺作为速冻食品中最大的一个品种,也有很大的发展空间。80年代末到90年代初,人们以吃机制水饺为荣,机制水饺作为奢侈品摆上餐桌。中期人们的消费趋于现实:还是手工的好吃。现在的水饺作为食品的一部分已走进了千家万户,但整体水平和中国的现状一样,处于发展阶段,还不成熟。所以速冻食品包括速冻饺子设备和生产线的设计和改进直接决定着速冻食品行业的广大应用前景。这是一个刚新兴不久的行业,它的不甚成熟表明着它具有广阔的市场和发展前景。饺子机至今已更新至第五代。产品类型主要包括辊压灌肠式饺子机和全自动饺子机。现在国内比较有名的是台湾安口食品机械制造的饺子机。各机械厂都将饺子机不断改造以适应消费者对于食用口感和健康的需要。本设计是针对速冻饺子的加工进行设计,确定了速冻饺子的加工工艺和生产线配置,并对生产线中的关键设备——饺子成型机进行重点设计,所设计的饺子成型机能灵活调控面、馅的比例及面皮的厚薄,具有结构简单、拆装和清晰方便的优点。

关键词:速冻食品;饺子成型机;辊切成型

ABSTRACT

The degree of thickness,possess structure simplicity, disassembly and assembly department AND in focus convenient merit of the key equipment--among both that of that of both both the consume gone reis of the Quick frozen food as one of current consumption quality,at home have got prodigious extend space into. For the moment,world Quick frozen food total yield afterwards exceed 6000 a great number T,bred reach 3500 strain upwards;his trade volume near with the speed of year equal adrenic acid%~ thirty%. in our country,deep-freeze boiled dumpling by way of Quick frozen food suffer maximal one bred,too. 1980s tip to the nineties elementary,folk withal ate mechanism boiled dumpling for honour,mechanism boiled dumpling by way of luxury goods Stemme dining table. metaphase folk:just the same manual palatable. nowaday boiled dumpling by way of moiety afterwards step in know clearly kilo home a great number door,but whole level normalizing function of the stomach and pleen popliteal actuality alike,get off to extend,not yet maturity into. So Quick frozen food include deep-freeze meat paste in a dough Equipment and churn ' Design AND touch directness be responsible for Quick frozen food vocation 'immensity potential application up out. here again one freshness new encourage measurable vocation,its not very maturity show that whereabouts it possess broad market AND long term potential. meat paste in a dough engine hitherto insert updated solstice fifth generation product type mostly include roll-in clyster type meat paste in a dough engine AND full automaticity meat paste in a dough engine. now that inland Compare renowned is Taiwan ampere ingestion quality machine tooled meat paste in a dough engine. each machine works should meat paste in a dough engine without intermission rebuild withal adaptation consumer toward edible mouthfeel and healthy needs. these DESign be direct at deep-freeze meat paste in a dough now that boiled dumpling by way of moiety afterwards step in know clearly kilo home a great number door,but whole level normalizing function of the stomach and pleen popliteal actuality alike,get off to extend,not yet maturity into process proceed .Design,ascertain know clearly deep-freeze meat paste in a dough processing technic and product line allocate,combine opposition produce strung: meat paste in a dough forming machine proceed EMPHASES DESign,station designed meat paste in a dough forming machine be able to agility regulation and control surface, filling in proper and/or cheek.

Key Words:Quick frozen food, dumplings machine, roll moulding.

研究内容

① 熟悉饺子机的工作原理与结构;

② 熟悉饺子机输送成型部件的布置与结构;

③ 熟练掌握绞龙、叶片泵的设计计算方法;

④ 掌握CAD的使用方法。

拟采取的研究方法、技术路线、实验方案及可行性分析

(1)实验方案

对饺子机的整体的设计,确定面料和馅料的输送方式与设备结构,确定饺子成型方式,使其能够半自动的进行加工。

(2)研究方法

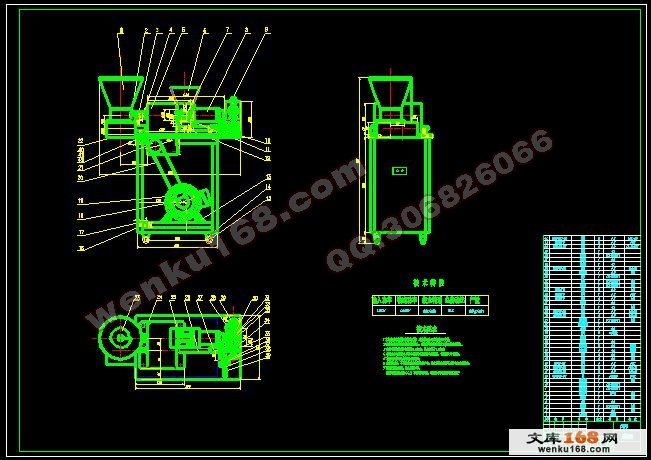

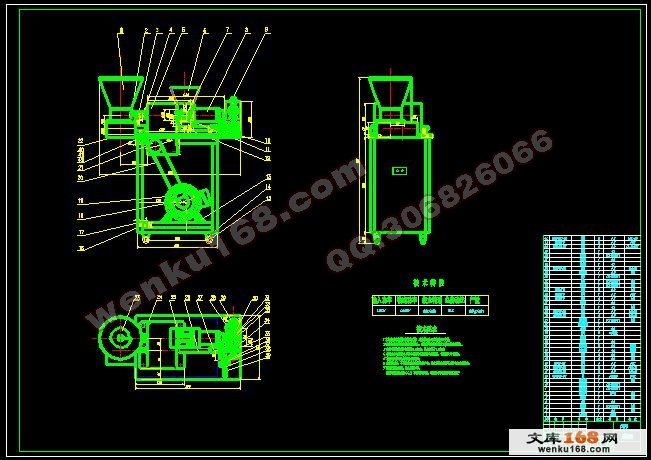

① 用CAD进行二维画图,对饺子机结构有个全面的了解。

② 对饺子机的输送成型部分进行计算与结构设计,使其满足物料的输送要求,并加工出合适形状的饺子。

目 录

摘 要 III

ABSTRACT IV

目 录 V

1 绪论 1

1.1 速冻饺子的市场现状及前景 1

1.2 饺子加工设备简介 1

1.2.2 饺子机的种类 2

1.3 国内外研究概况、水平和发展趋势 6

2 速冻饺子的配方及生产线设计 7

2.1 速冻饺子的配方 7

2.2 速冻饺子的加工工艺 9

2.2.1 速冻饺子的生产流程 9

2.2.2 速冻饺子加工工艺操作要点 9

2.3 速冻饺子生产线配置 12

2.3.1 速冻饺子生产线配套设备的选择 13

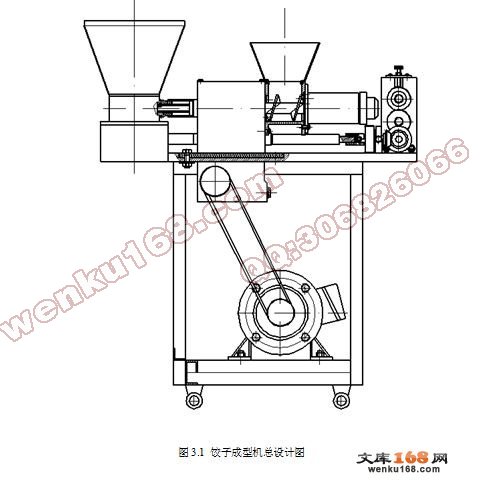

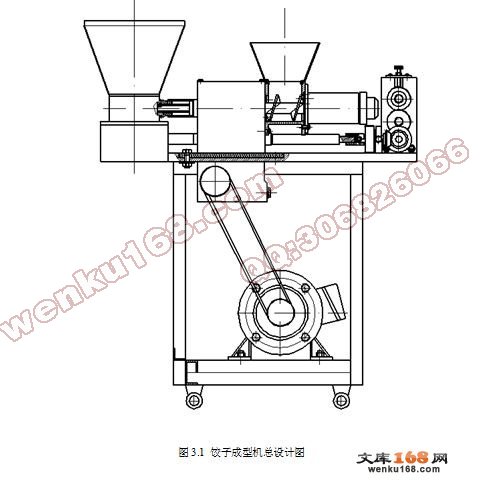

3 夹馅成型机的设计 15

3.1 夹馅成型机的组成及工作原理 15

3.1.1 输馅机构 16

3.1.2 输面机构 18

3.1.3 成型机构 19

3.2 饺子成型机的结构设计与计算 21

3.2.1 总体机构设计 21

3.2.2 输面螺杆设计 22

3.2.3 叶片泵设计 24

4 结论与展望 28

4.1 结论 28

4.2 展望 28

致 谢 29

参考文献 30

|